Sodium Silicate Plant (using Rice Husk Ash as major raw material)

Rice Husk Ash is generated by all industries using rice husk fired boilers, which includes rice mills and other industries like edible oil plants etc. Large amount of Rice Husk Ash (RHA) is generated in countries like India, Bangladesh etc. which finds very little use and mostly get dumped. The RHA in itself is a pollutant that pollutes land and consequently water bodies during rainy season. The low bulk density of RHA also causes it to pollute air during dry seasons. Net Works Exports provides complete turn key solution to utilize RHA as a raw material to produce industrially important Sodium Silicate which helps reducing pollutant to an extent.

Our process helps reducing green house gas generation (i.e., CO2) vis-a-vis conventional method of producing Sodium Silicate from quartz Sand and Soda Ash route. Typically, a 30TPD plant will cut down CO2 generation to the tune of 12,000 - 15,000 T/Year. When Rice Husk is used to produce steam for the process, the project can be termed as carbon neutral. The product may be called green product as it used agricultural residue as major raw material.

Advantages of using this process vis-a-vis conventional process

- More environment friendly (saving in CO2 gas generation)

- Lower operating temperature regime - easier process control

- Lower energy consumption

- Lower production cost

- Can make all possible grades - both neutral and alkaline grades.

- Better quality control

- Local and widely available raw materials - foreign exchange saving (specific to Bangladesh)

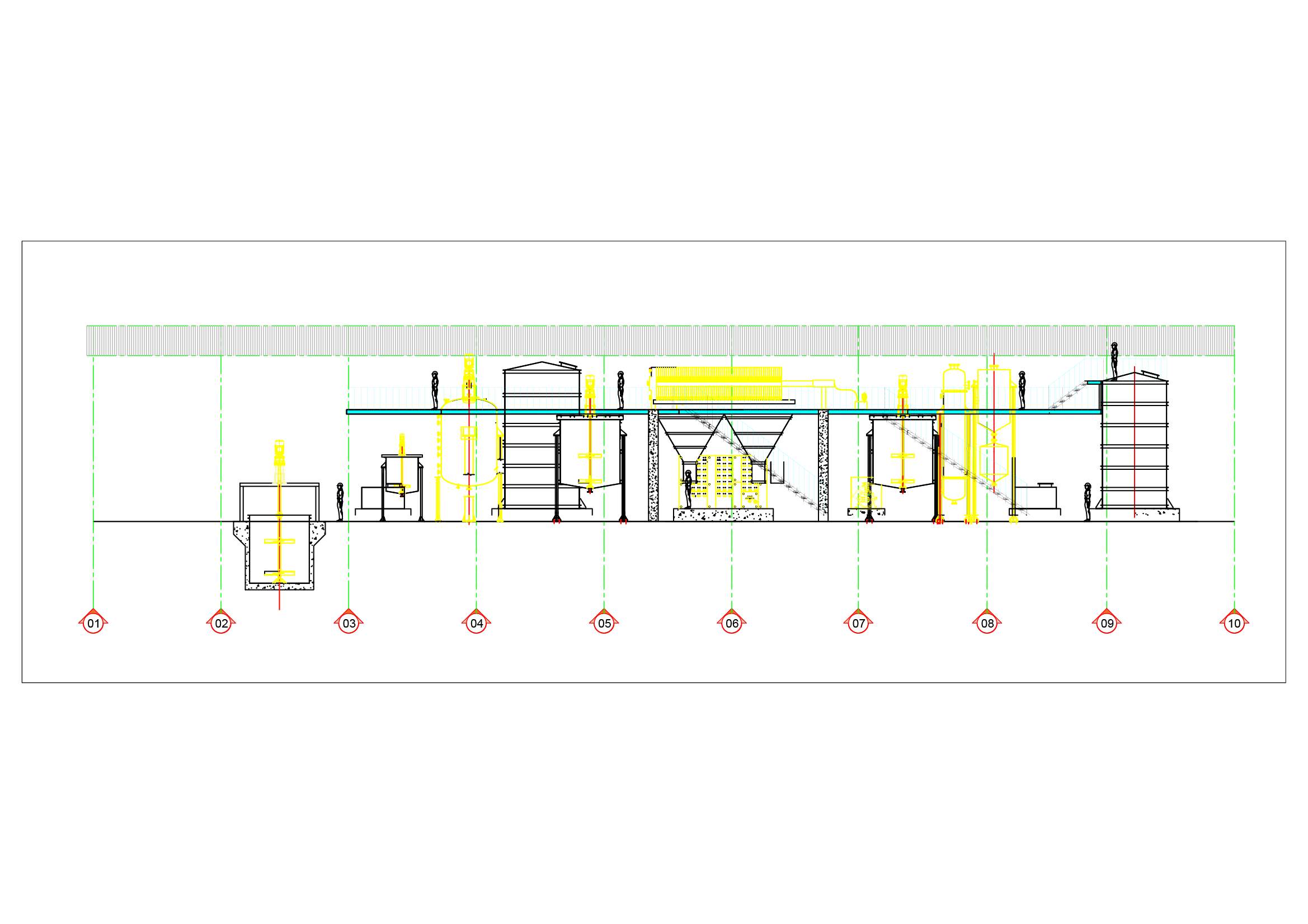

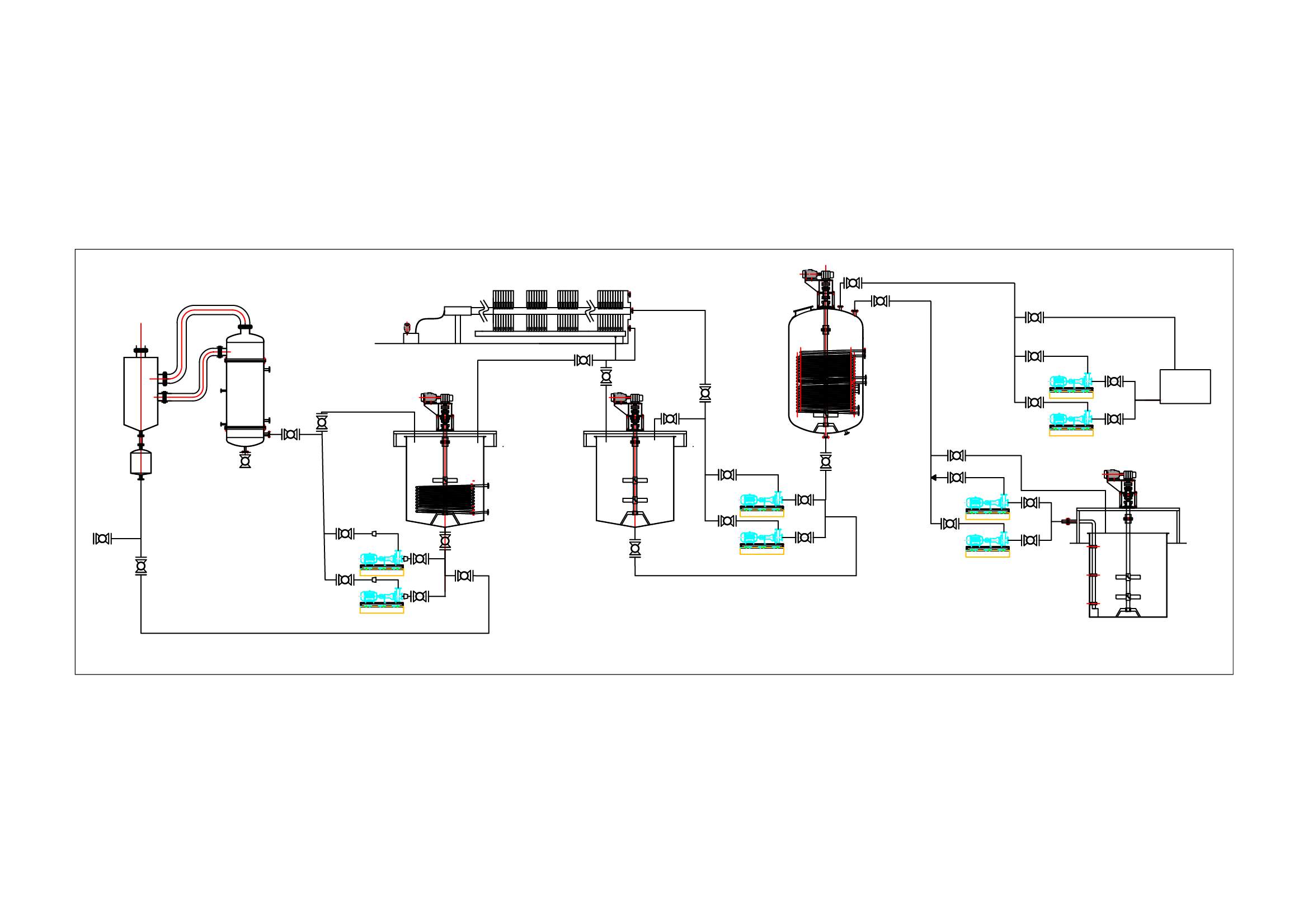

Gallery

Sodium Silicate Plant

Sodium Silicate Plant

Sodium Silicate Plant

Sodium Silicate Plant

Sodium Silicate Plant

Sodium Silicate Plant

Sodium Silicate Plant

Sodium Silicate Plant

Sodium Silicate Plant

Sodium Silicate Plant

Sodium Silicate Plant

Sodium Silicate Plant

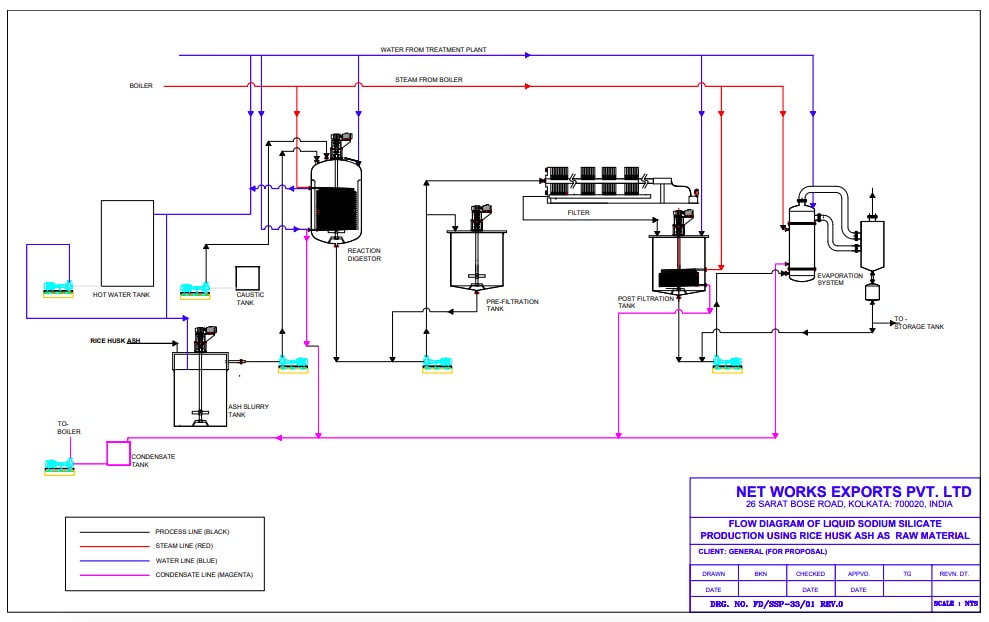

Glimpse of the basic process ( Flow Chart)

Project Videos

We aim higher, so that you can achieve better, each time.